ROV Team continues to assemble robots during winter break

January 12, 2019

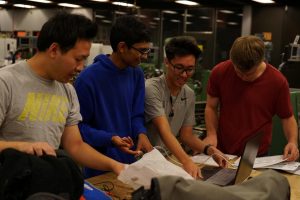

While most classrooms locked their doors to enjoy the holiday, Diablo Valley College’s ROV Team remained open, as they continued constructing their robotic submersibles, that are planned to launch during the Marine Advanced Technology Educational (MATE) competition in Monterey Bay.

Since their official inception, during the 2018 spring semester, there have been multiple advancements related to the actual design of the ROV, but the organization’s progress has been accompanied by an impactful setback. The team was given a grant by the Workforce Development program, a system designed to instill workers with high quality skills necessary for a professional work environment.

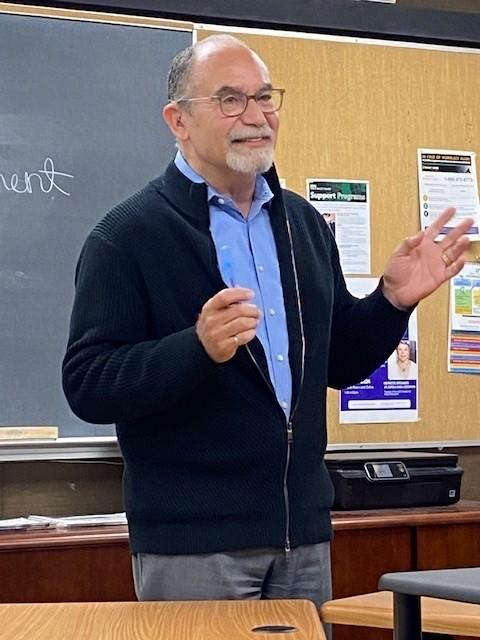

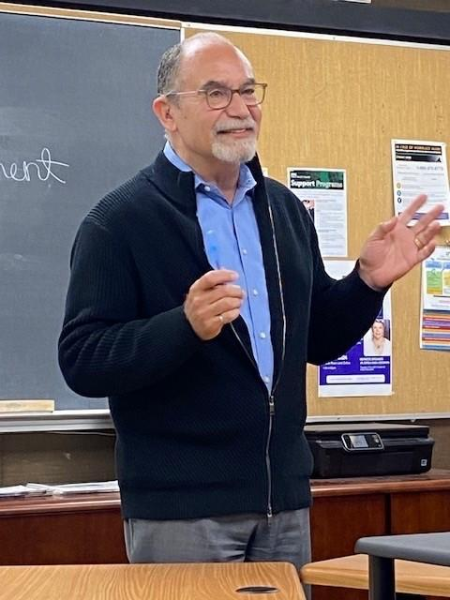

This grant was going to serve as the primary source of funding, as they approach the competition taking place on May 11. Even though it would be an opportunity for financial stability, the grant won’t actually be available until fall 2019, according to the head of the ROV Team Whitman Hall.

For this new team, “funding has definitely been an issue,” said Hall.

Despite Hall and his teammates approaching a significant obstacle to overcome, they still decided to meet over the winter break to design their primary and secondary ROV body. During their meeting on Jan 10, which lasted from 10 a.m. to 8 p. m., a prominent issue arose when troubleshooting a machine called a bandsaw, that is crucial to building the actual parts in-house. Without it, there wouldn’t be any pieces to assemble.

The manufacturing liaison, Ian Wenck, spent most of that day running back and forth between his contribution to their personally crafted online blueprint designs, servicing the bandsaw machine, and working with the computer numerical control (CNC), which can cut through metal pieces like butter.

“I’ve done both manual machining and the automated, so I kind of have a good concept of how things can be made,” said Wenck. “You can design a part but the question is, can you make it?”

The larger CNC machine used by Wenck can also manufacture the parts for their primary ROV, however, there is a smaller CNC machine, called a handibot, that is essential for creating the second mini-ROV. One that will be able to pop out and work with tighter areas that the primary robot can’t reach, deep within the ocean.

While Wenck’s hands were already full, another member had to learn how to competently use the handibot. Without anyone capable of doing so, they would have been set-back countless hours, although, when Aria Ghazvini stepped up, he acquired the skills necessary to use it in one day. By the end of their session, he created the required part. Ghazvini’s accomplishment had his teammates, who stayed late with him, astonished at his potential to use the handibot with such a sort amount of time in acquiring the knowledge to use it.

“The only person who knows how to operate (the handibot) right now is Hall,” said Ghazvini. “Nobody else pretty much knows how to use it at all. So, it’s good to diversify out of a bunch of people, because Whitman is usually busy managing the team or troubleshooting other stuff.”

As they begin putting together each part of the ROV, and before they even start the testing phase, there are a few goals Hall has set before his team members. First, the financial stability of the organization is critical for their capacity to attend the competition. On Jan 15, they will reach out to neighboring companies in order to obtain funds, which they hope will lead to an acquisition allowing enough support to drive down, and take part at the MATE competition in Monterey.

In the coming weeks, they will also need to cut indispensable aluminum components for both ROVs, while the electrical team will begin to link sensors within the framework that identify leakage, and respond by contacting their computer at the surface. In addition, they will continue to develop the most practical set of cameras for their submersibles.

“What will determine our success, I think, is the meeting where we sit down and decide to build the robotic arm,” said Hall.